Internal Corrosion Control

Corrosion Control has become vital in the success of the Industry’s production goals. Corrosion mitigation is paramount to extending the lifespan of downhole tubulars and casing. Permian Enterprises offers a complete line of Premium Products to protect our customer’s investment in the harshest of downhole environments.

With 3 Internal Application Facilities, Permian Enterprises offers our customers both the highest quality products they deserve at the production capacity they demand. Collectively, Permian Enterprises boasts a production rate unmatched in the industry. With all 3 facilities located in the Permian Basin, our customers have easy access to their inventory when they need it, where they need it.

Permian Enterprises has various options of IPC (Internal Plastic Coatings) to cover a wide range of needs. Whether dealing with Water Injection, High Temperature, or High Abrasive Environments, Permian Enterprises has a coating to meet our customer’s demands.

1n 2004, Permian Enterprises built the first of two internal plastic coating facilities to meet the demand of the growing oil boom in the Permian Basin. In 2007, a second plant had to be built to keep up with the needs of our customers.

The plants run six days a week. The coating plants provide the full spectrum of coatings desired for use in the Permian Basin. Our customer list is large. From majors to the smallest independents Permian Enterprises gives everyone the outstanding service that customers of Permian Enterprises have come to expect.

For more information call (432) 332-0903.

-

IPC 1505

Thick-film fusion bond epoxy powder coating with superior handling characteristics for CO2. -

IPC-1505AR

Thick film, fusion bond powder coating, modified for enhanced abrasion resistance. -

IPC 1850

Thick film fusion-bond powder coating based on cresol-novolac chemistry -

IPC-1850AR

Thick film fusion bond powder coating based on Cresol Novolac chemistry, modified for enhanced abrasion resistance. -

IPC 2000

Modified epoxy powder coating designed for high-temperature.

IPC 1505

IPC-1505 is a high-performance, economic epoxy powder coating designed to protect injection strings in multiple applications in the Oil & Gas industry. Its superior flexibility allows for the application on large diameter pipe. IPC-1505’s versatility makes it an excellent choice for protecting tubing and casing strings, increasing the life span of the well and lowering operating expenses.

Recommended Services

- CO2 Injection WAG

- Oil/Water/Gas Production

- Brine Injection/Disposal & Rod Pump Wells

- Flow Lines

- Line Pipe

Benefits

- Excellent Flexibility

- Moderate Acid/Caustic Resistance

- Excellent Adhesion

Characteristics

- Color: Tan

- Generic Type: Epoxy

- Primer: Phenolic

- Temperatures: 250° F (121° C)

- Thickness: 10-20 dry mils

More Product Information

Temperatures: 250° F (121° C)

Pressure: High Pressures

Test Conditions: Excellent Temperature Characteristics

Time Period: Excellent

IPC-1505AR

IPC-1505AR is a high-performance, economic epoxy powder coating specifically designed to have the highest degree of abrasion resistance to reduce the impact of abrasion and erosion created by high flow rates while maintaining excellent corrosion resistance and flexibility.

Recommended Services

- Oil and Gas Production

- Gas Lift

- Rod Pump and Injection Wells

- Line Pipe

- WAG

Benefits

- Reduces Mechanical Damage

- Excellent Abrasion Resistance

- Excellent Flexibility

- Improved Flow Dynamics

Characteristics

- Color: Tan

- Generic Type: Modified Epoxy

- Primer: Phenolic

- Temperatures: 250° F

- Thickness: 10-20 dry mils

More Product Information

Temperatures: 200° F

Pressure: High Pressures

Test Conditions: Excellent Flexibility

Time Period: Excellent

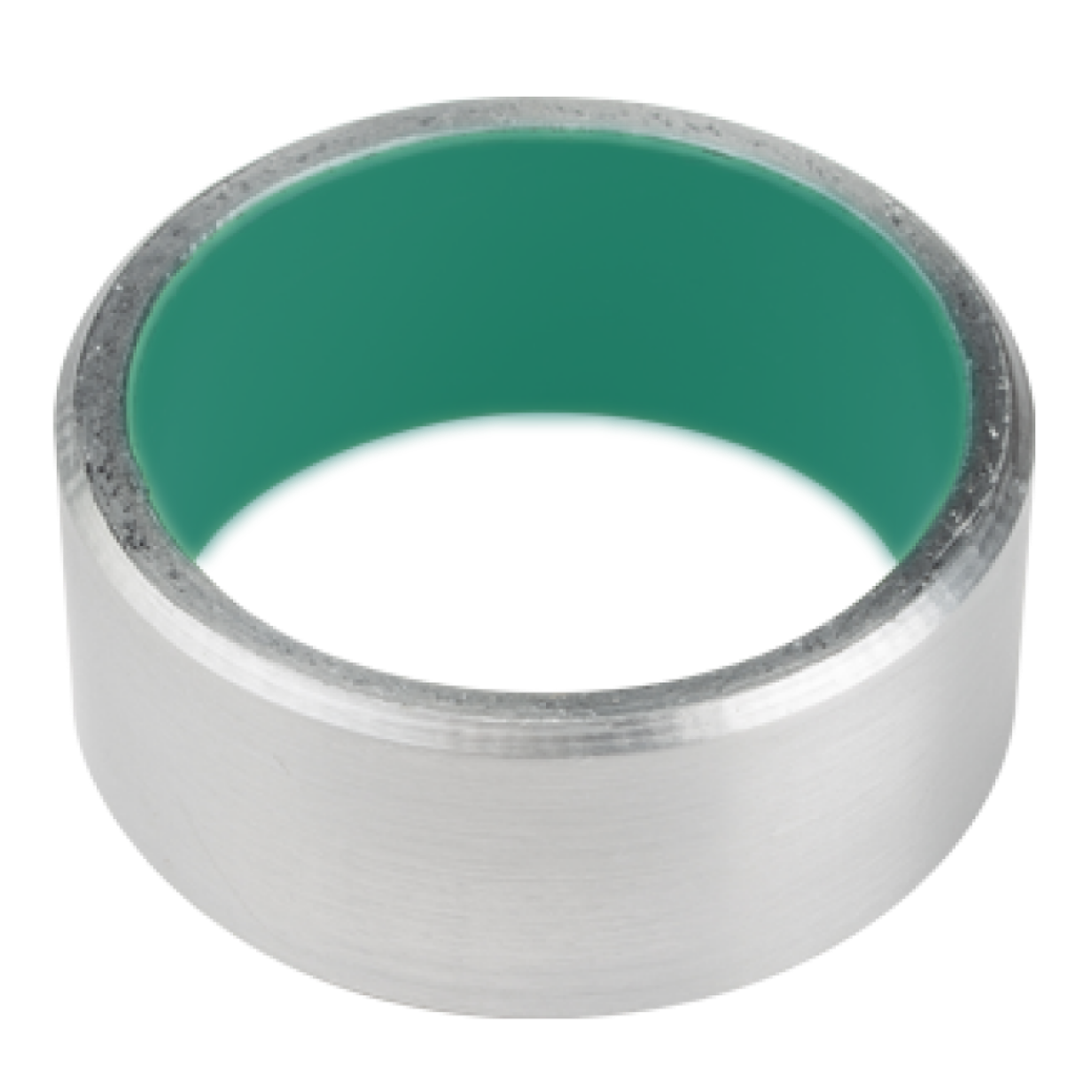

IPC 1850

IPC 1850 is a thick film fusion-bond powder coating based on cresol-novolac chemistry with excellent temperature and corrosion protection characteristics. It has excellent resistance to sweet and sour environments in combination with abrasion resistant to dissolved salts.

Recommended Services

- Oil/Water/Gas Production

- Gas Lift

- Rod Pump/Brine Injection/Disposal Wells

Benefits

- Paraffin Resistance

- Excellent Acid/Caustic Resistance

- Excellent Abrasion Resistance

Characteristics

- Color: Green

- Generic Type: Cresol Novolac

- Primer: Phenolic

- Temperatures: 300˚ F (150˚ C)

- Thickness: 10-20 dry mils

More Product Information

Temperatures: 300˚ F (150˚ C)

Pressure: High Pressures

Test Conditions: Excellent Resistance to Sweet and Sour Environments

Time Period: Excellent

IPC-1850AR

IPC-1850AR is a high-performance epoxy powder coating designed to offer the highest degree of protection in terms of chemical resistance, abrasion resistance, and elevated operating temperatures. IPC-1850AR provides unparalleled protection when it comes to the most corrosive elements found downhole in the Oil & Gas industry.

Recommended Services

- Water/Gas Production

- Injection Wells/Disposal Wells

- WAG Wells

Benefits

- Excellent Abrasion Resistance

- Hydraulic Improvement

- Excellent Corrosion Resistance

- Elevated Operating Temperatures

Characteristics

- Color: Green

- Generic Type: Cresol Novolac

- Primer: Phenolic

- Pressure: up to 8,500 psi

- Temperatures: 300°F

- Thickness: 10-20 dry mils

More Product Information

Temperatures: 350°F (174°C)

Pressure: Up to 8,500 psi

Test Conditions: Excellent Wireline Resistance and Paraffin Buildup

Time Period: Excellent

IPC 2000

IPC 2000 is a proven generation of high temperature fusion bond powder coating that provides excellent mechanical and chemical resistance. It is a modified epoxy powder which also offers excellent wireline resistance and paraffin buildup. IPC 2000 is resistant to a wide variety of downhole environments to 350ºF.

Recommended Services

- Water/Gas Production

- Injection Wells/Disposal Wells

- WAG Wells

Benefits

- Paraffin Resistance

- Abrasion Resistance

- Acid Resistance

Characteristics

- Color: Dark Green

- Generic Type: Modified Epoxy

- Primer: Phenolic

- Pressure: up to 8,500 psi

- Temperatures: 350°F (174°C)

- Thickness: 10-20 dry mils

More Product Information

Temperatures: 350°F (174°C)

Pressure: Up to 8,500 psi

Test Conditions: Excellent Wireline Resistance and Paraffin Buildup

Time Period: Excellent