Permiline

Permiline is generally used for transporting corrosive oil or water. However, where the water to be handled is known to have an extremely low pH (as in the case of CO2 injection or production) or should future requirements call for the flexibility of being able to acidize a potential scale build up, then FLOUROLINE should be considered. Regardless of which of the products is selected, the customer is assured of a long-lived and highly versatile interior coating.

Protective Mechanism: The protective mechanism of cement lining stems from passivation at the steel-cement contact area due to increased pH, and the long-term reaction between cement and pozzolanic materials which results in self-healing of small cracks in the lining.

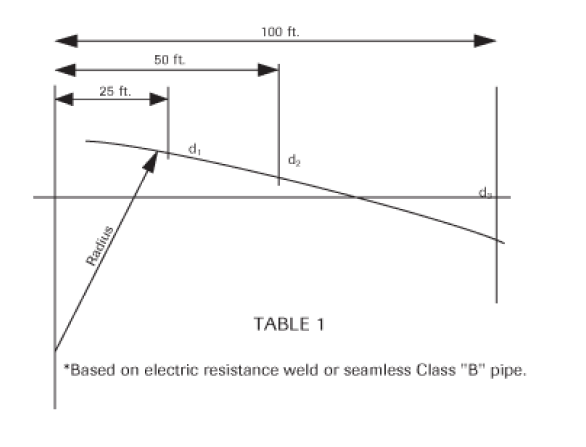

Laying: Pipelines are customarily deflected to follow terrain contours. The “rule of thumb” for cement-lined pipe is: that no damage will occur to the lining provided the yield point of the steel is not exceeded. For design purposes see the following chart and table. Should abrupt bends be anticipated, then cement-lined fittings must be used.

Because the cement lining has a coefficient of thermal expansion virtually identical to the steel tube, no consideration needs to be given to temperature changes.

Joints may be coupled by (1) welding – using a special gasket (2) the conventional T&C joint with PERMITEK joint compound (3) or the seal grooved type coupling. There are other trademarked coupling systems available.

Field cuts can be made with either saws or cutting torches; however, rough lining ends should be repaired with our easily applied patching compound.

Handling: Care should be taken to prevent either denting or permanent distortion of the steel tube. Such damage can result from throwing lined pipe from trucks, allowing it to strike a hard object, or exceeding the legal overhang during transport. Hooks or other objects should not be inserted into the pipe ends.

Recommended Services

- CO2 injection – WAG

- Brine injection (water flood, disposal)

- Flow lines/line pipe

Benefits

- Long service life

- Low cost

- Good for reconditioning pipe

Characteristics

- Conventional Portland cement

- No pressure limits

- Temperature: 350°F

Permiline Curvature